PRI 2017: Fleece Performance’s Billet Block and Intake Manifold

This article was originally published on December 7, 2017 by Artie Maupin on Enginelabs.com

PRI 2017: Fleece Performance’s Billet Block and Intake Manifold

By ARTIE MAUPIN DECEMBER 07, 2017

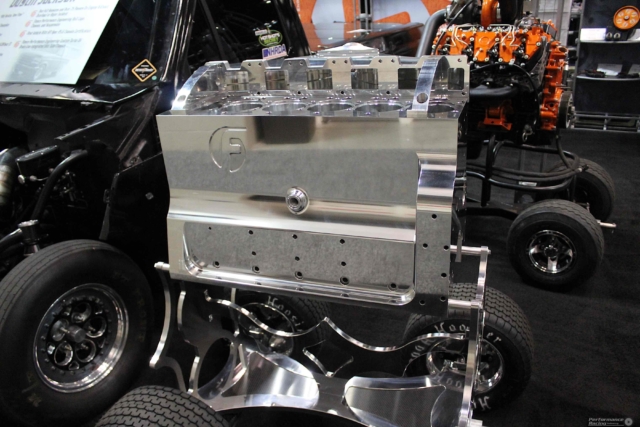

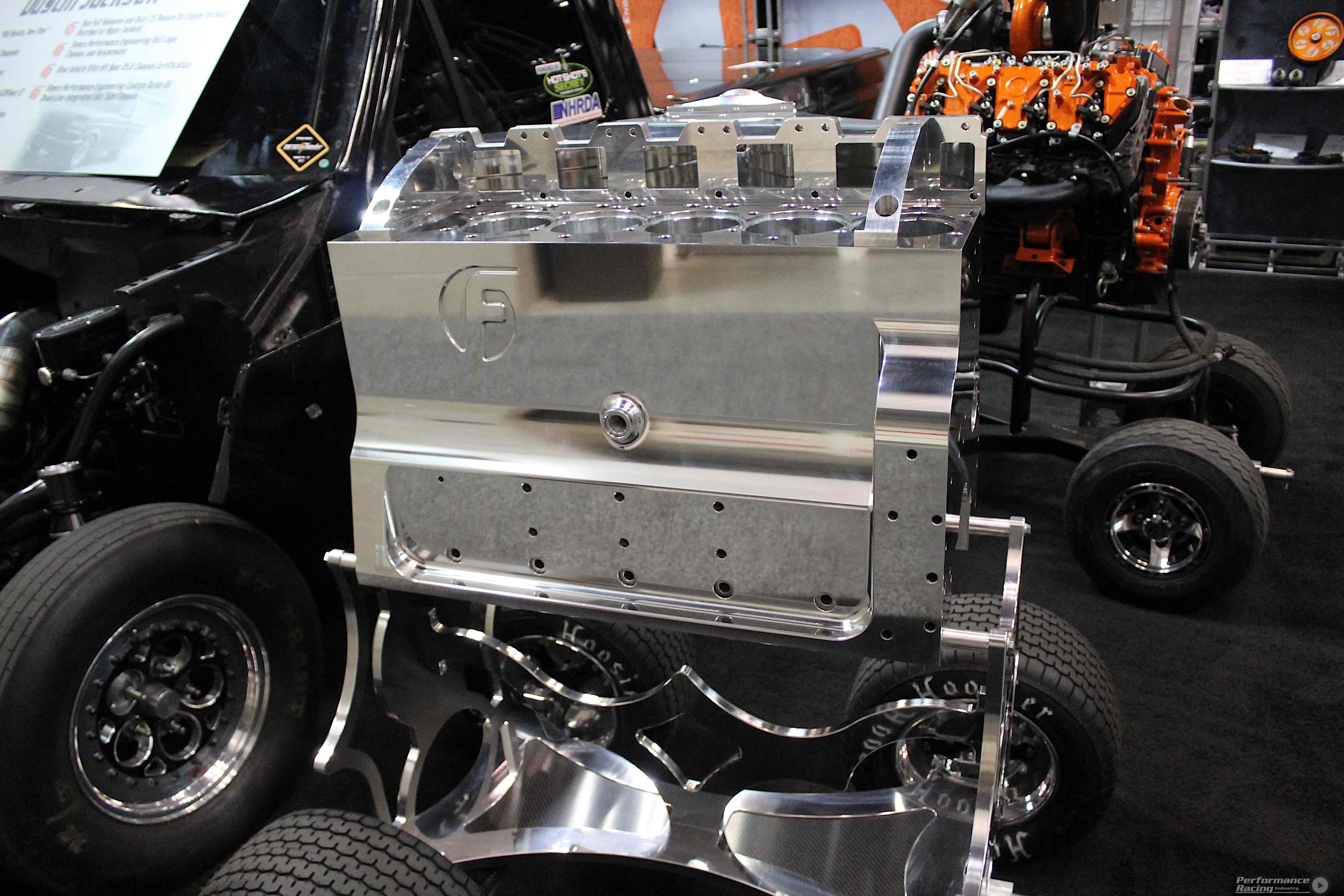

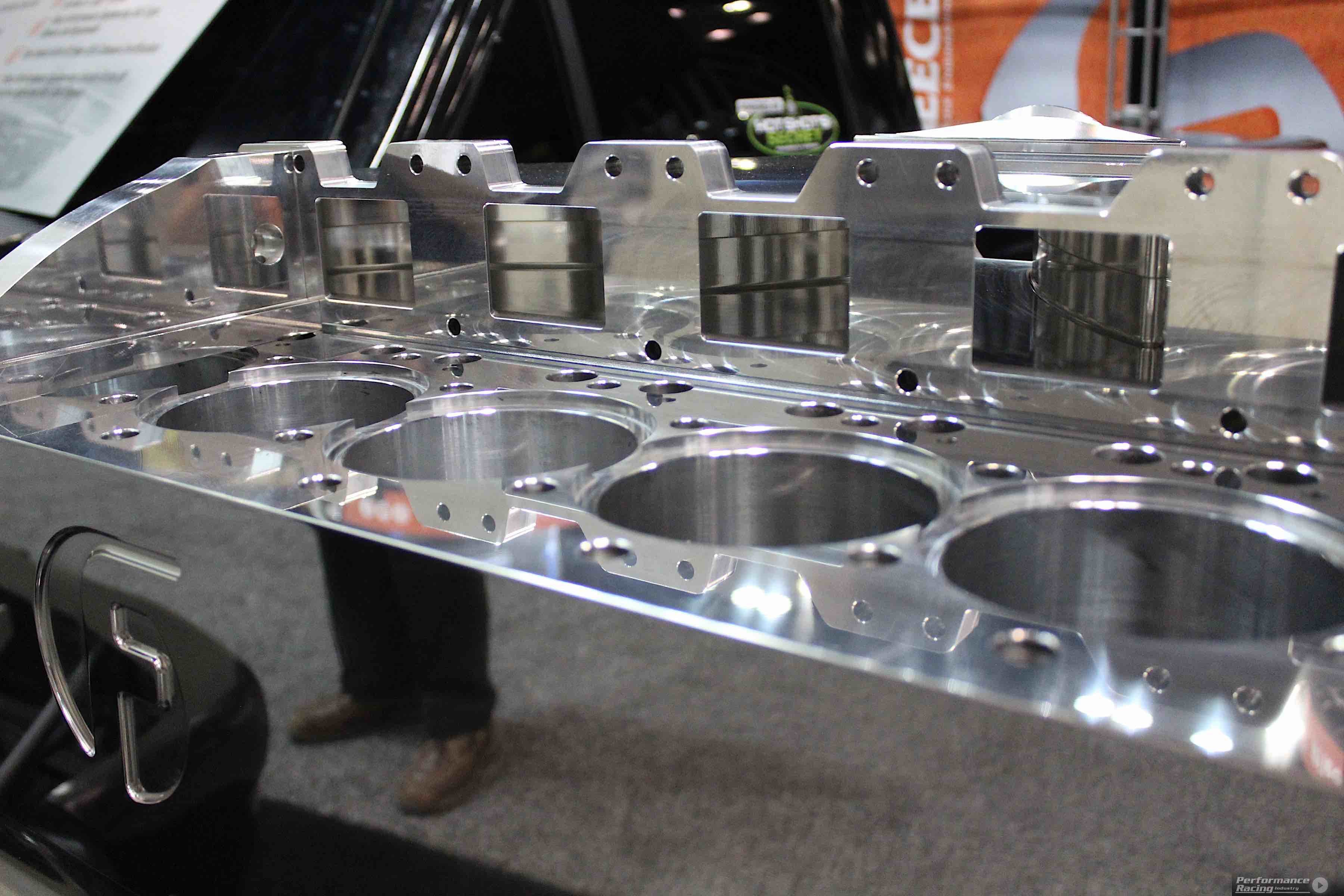

While this isn’t the debut of the billet aluminum engine block, it’s being revamped into a stronger and lighter design. Fleece Performance and Engineering, along with Freedom Racing Engines have teamed up to better the original block to obtain more power and offer better reliability.

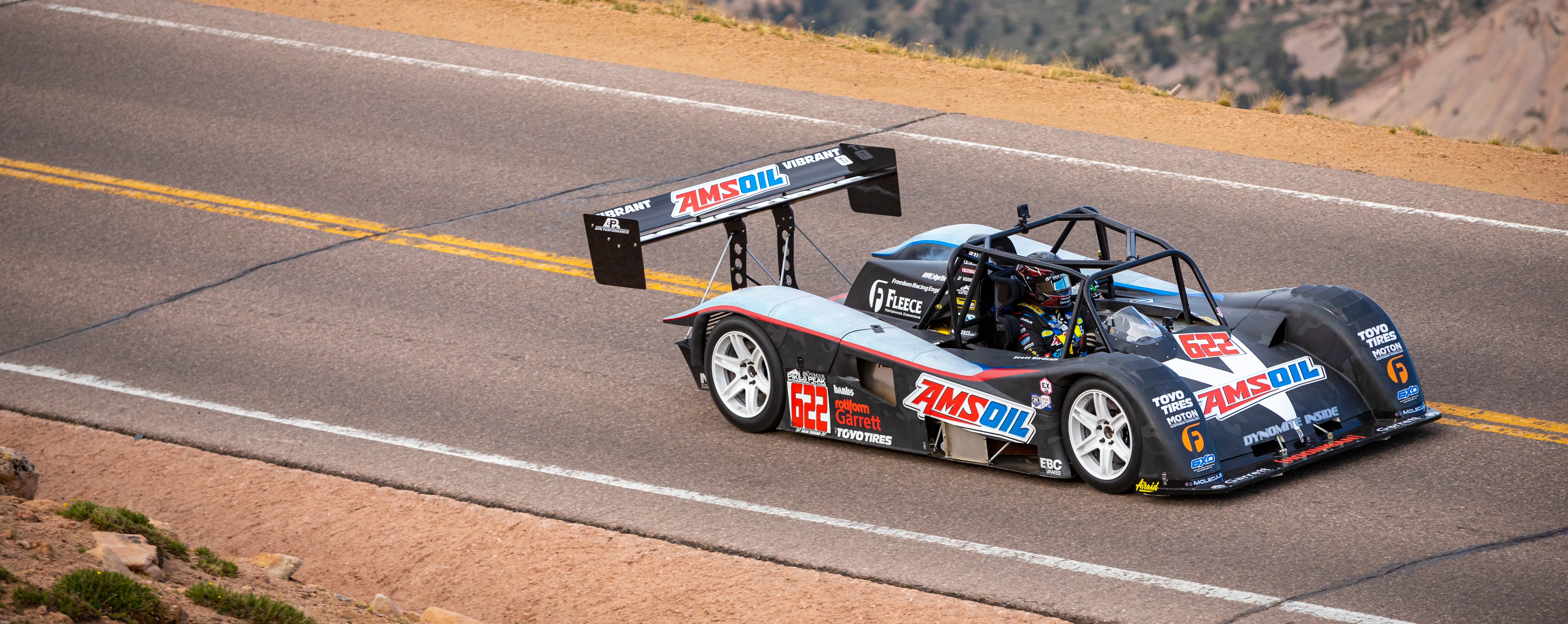

“We have a lot of interest in the drag racing scene with drivers striving to lose as much weight as possible and that’s why we’ve designed the billet block”, said Corbin Murphy, of Fleece Performance. “With our drag truck in mind, this could be an option to cut even more weight off of our truck that obviously is clashing with weight loss.”

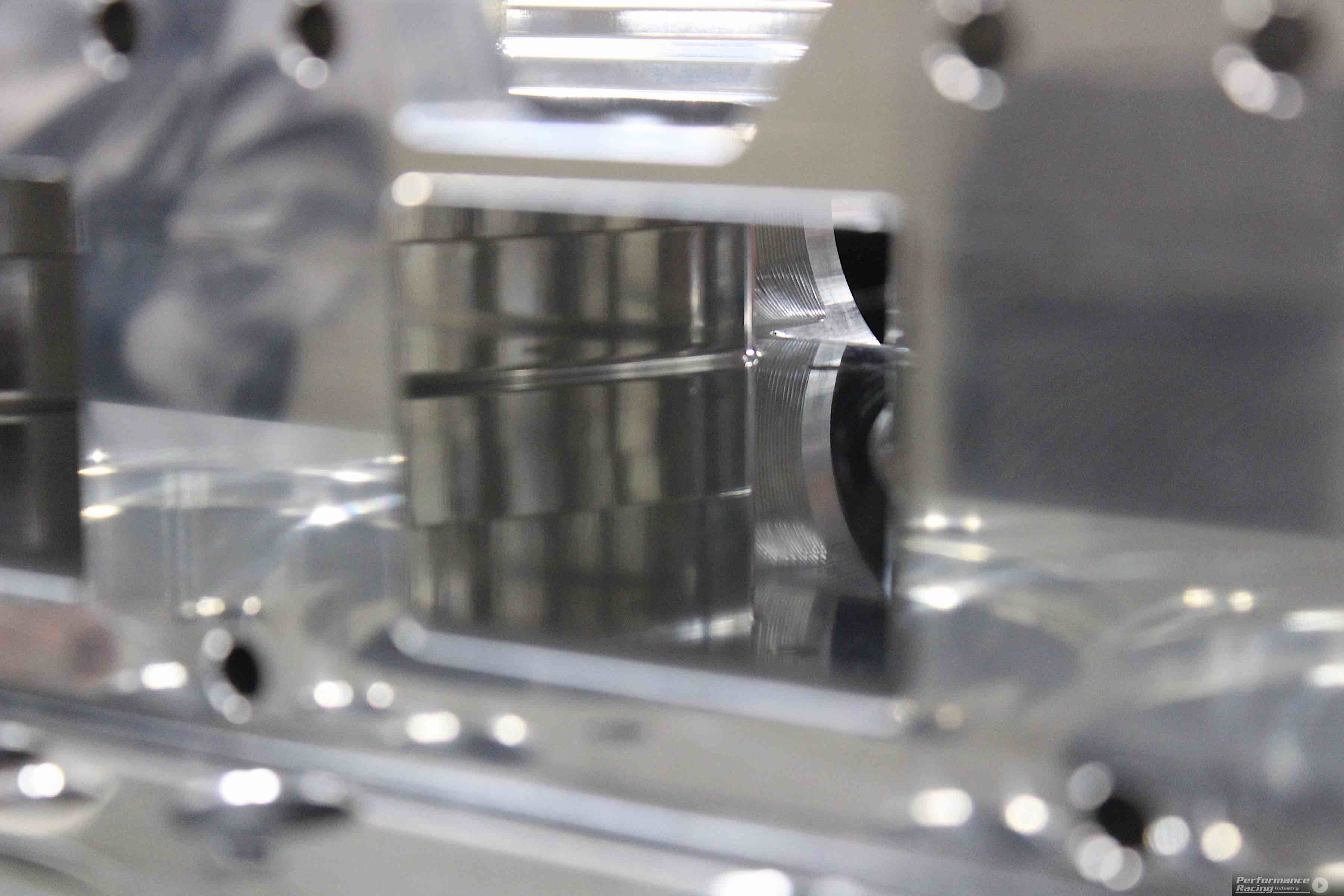

This 6.7-liter engine is equipped with cross main bolts as well as the traditional bottoms. This will allow for maximum strength on the bottom end.

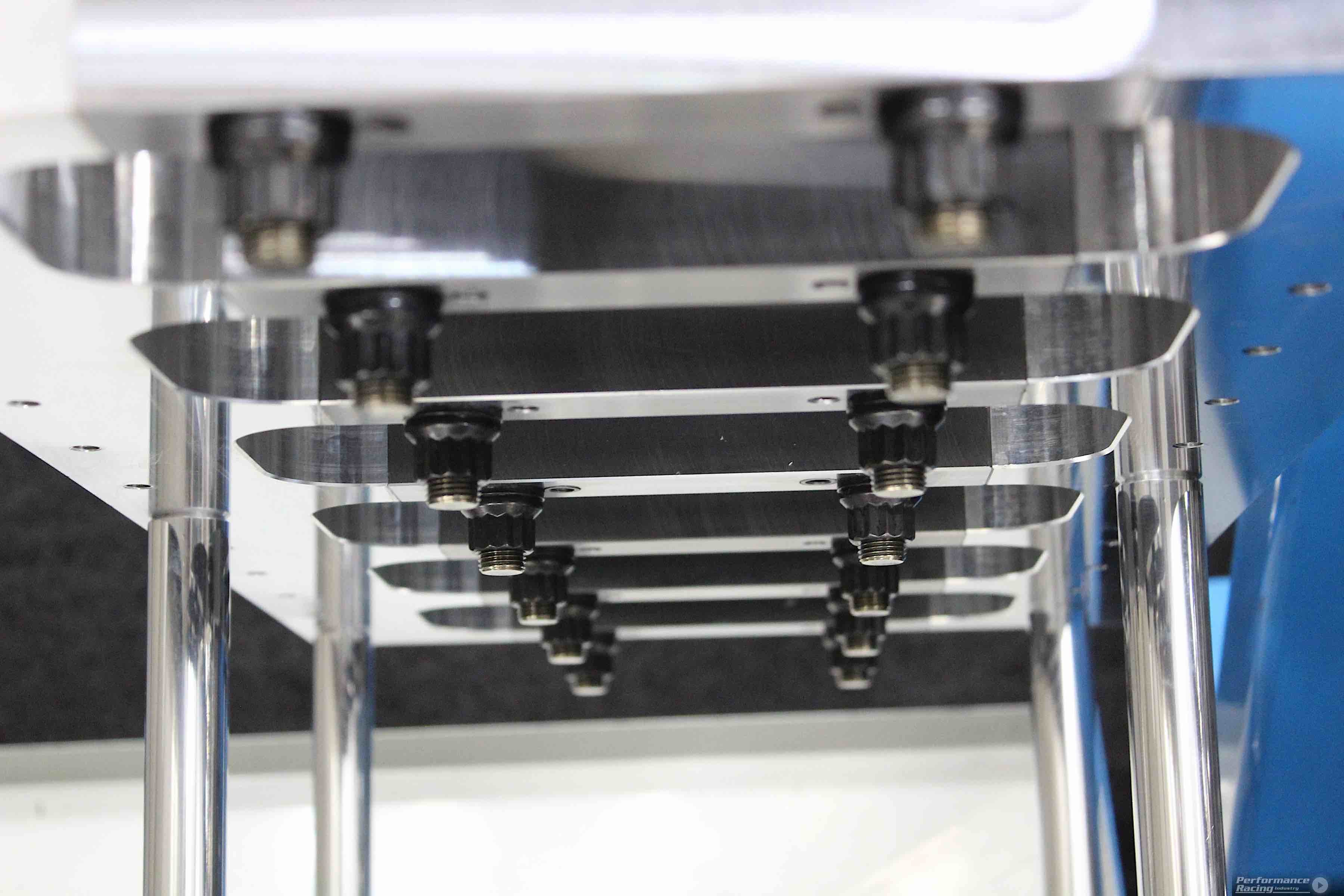

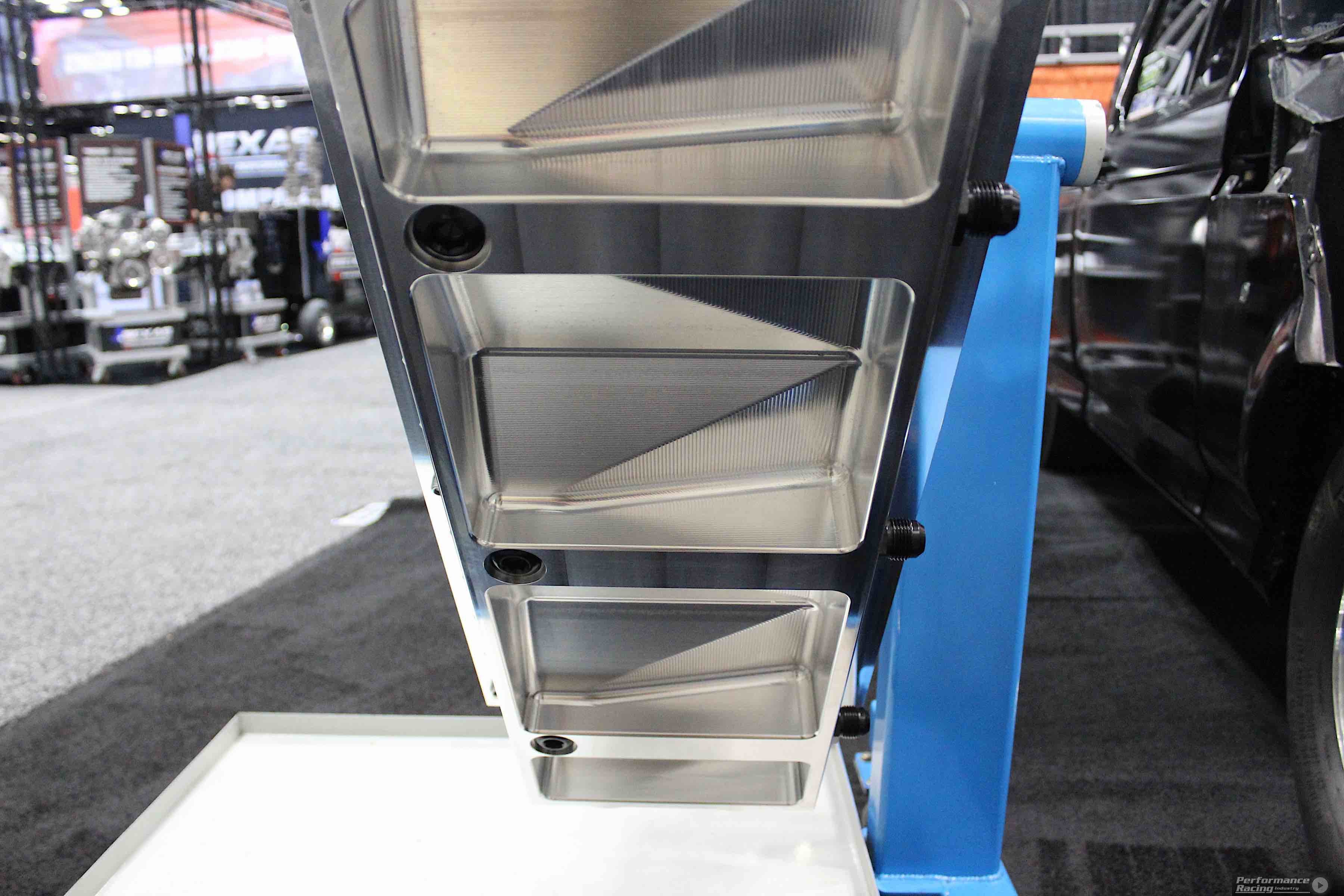

Matching with the lightweight super-engine is the new billet aluminum intake manifold. “The Cummins engines traditionally don’t have a good way getting to cylinders one and six.,” Murphy said. “While the popularity of cutting the intake off the engines has climbed, Chase Fleece designed this intake with dividers that will distribute the air properly and equally throughout the cylinders.”

Using HAAS machining, Fleece has the resources to put an entire engine inside and cut the bottom of these blocks, flip the engine over and cut the top of the block to specs as well.

This combination of the engine block and intake manifold is worthy of supporting the range of 3,000-horsepower. For more information on the billet intake manifold and engine block, be sure and check out Fleece Performance and their website.